Introduction

The demand for efficient and reliable lifting equipment is paramount in the competitive steel industry. As a leading provider of lifting solutions, DQCRANES recently had the opportunity to work with a Pakistan Steel Plant to upgrade their lifting equipment, specifically requiring a top running wire rope hoist with a double girder.

Client’s Background

The client came from a steel plant in Pakistan, which is known for its commitment to quality and operational excellence. With a focus on continuous improvement, the plant sought to enhance its lifting capabilities by investing in advanced lifting equipment. The client’s emphasis on safety, reliability, and efficiency guided their decision to upgrade their lifting solutions.

Client’s Requirements

The client’s requirement for lifting equipment update included the need for a robust and high-capacity hoist that could seamlessly integrate with their existing infrastructure. The specific demand for a top running double girder hoist highlighted the client’s emphasis on precision and heavy-duty lifting operations. Understanding the critical nature of their operations, the client sought a solution that would offer enhanced performance and durability.

Double Girder Hoist Solutions from DQCRANES

Drawing on our expertise in providing tailored lifting solutions, our team at DQCRANES embarked on designing a customized top running double girder electric trolley hoist to meet the client’s requirements. Through detailed consultations and site assessments via online video, we gained valuable insights into the specific operational challenges and environmental factors at Pakistan Steel Plant. This information was instrumental in shaping our design approach, ensuring that the final solution would align seamlessly with the client’s operational needs.

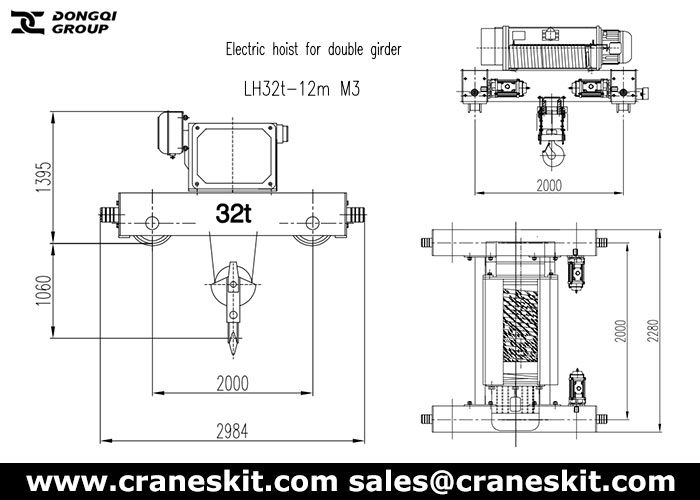

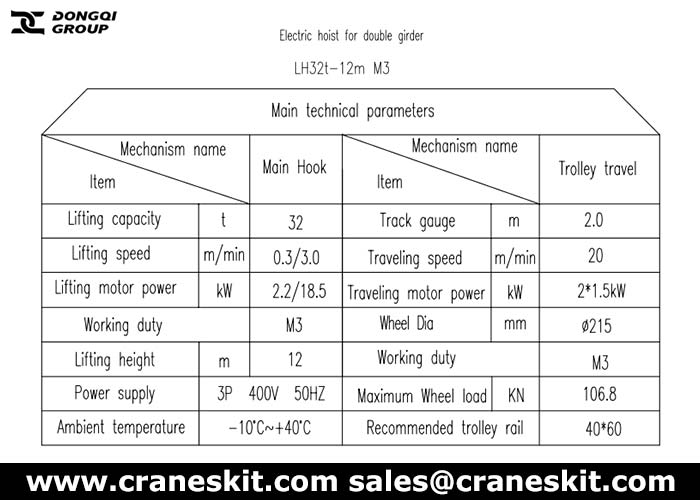

Design Details

The design process focused on integrating advanced features to deliver optimal performance. The incorporation of double speed functionality in the wire rope hoist was a key aspect of the design, enabling precise control during lifting and positioning operations. The double speed capability offered enhanced flexibility, allowing for efficient handling of varying loads and operational requirements.

- Capacity: The double girder hoist is capable of lifting and moving loads up to 32 tons, making it suitable for handling heavy-duty materials commonly found in steel plants.

- Double Speed: The 32 ton electric rope hoist is equipped with a double speed feature, allowing for precise control and efficient operation. This enables the hoist to handle a wide range of loads with varying weights and dimensions.

- Top Running: The double girder hoist is designed for top running applications, providing flexibility and ease of movement across the length of the double girder. This configuration ensures optimal use of space and allows for seamless integration into existing plant layouts.

- Wire Rope: The top running hoist utilizes high-strength wire rope for lifting, ensuring reliability and safety during operation. The wire rope is designed to withstand heavy loads and constant use, making it ideal for the demanding conditions of steel manufacturing facilities.

- Double Girder: The wire rope hoist for sale is paired with a double girder configuration, providing enhanced stability and load-bearing capacity. This design is well-suited for handling large and heavy materials commonly encountered in steel production processes.

Design Features

- Robust Construction: The 32 ton electric hoist is constructed with high-quality materials and components to withstand the rigors of industrial operations. Its robust design ensures long-term reliability and minimal downtime, contributing to increased productivity and efficiency.

- Precision Control: The double speed hoist allows for precise control during lifting and lowering operations. This level of control is essential for handling delicate or oversized loads with accuracy and safety.

- Safety Measures: The double girder electric hoist is equipped with advanced safety features to protect both personnel and valuable assets. These include overload protection, emergency stop functions, and comprehensive safety monitoring systems.

- Customization Options: Our electric hoist for sale can be tailored to meet specific requirements, including customized lifting heights, speed variations, and specialized control systems. This flexibility ensures that the hoist can be optimized for the unique needs of the Pakistan Steel Plant.

- Easy Maintenance: The electric wire rope hoist is designed for ease of maintenance, with accessible components and simplified service procedures. This minimizes downtime for routine inspections and repairs, contributing to overall operational efficiency.

Single Girder Hoist vs Double Girder Hoist

DQCRANES offers single and double girder wire rope hoists for standard industrial applications, with standard capacities of from 2 to 80 tons. While single girder wire rope hoists are suitable for a range of lifting applications, the specific requirements of Pakistan Steel Plant necessitated the use of a double girder configuration. The double girder design offers several advantages for heavy-duty lifting operations, including:

- Increased Load Capacity: Double girder hoists are capable of handling significantly heavier loads compared to single girder hoists, making them ideal for industrial applications with high-capacity lifting requirements.

- Enhanced Stability: The dual girder configuration provides increased stability and minimizes deflection, ensuring precise load control and minimizing sway during lifting operations.

- Versatility: Double girder hoists are well-suited for handling a diverse range of loads, offering flexibility in industrial settings where varying load sizes and weights are encountered.

Production and Delivery

The production and delivery process was executed with precision, taking into account logistical considerations and timelines crucial to the client’s operational schedule. Our team worked closely with the client to coordinate installation and commissioning, providing comprehensive support to ensure a seamless transition to the new lifting solution.

Result

Following the successful installation and commissioning of the 32 ton double girder electric hoist with double speed, Pakistan Steel Plant provided positive feedback on the performance and reliability of the solution. The enhanced lifting capabilities contributed to improved operational efficiency, reflecting the successful alignment of the tailored solution with the client’s specific requirements.

Contact us

For more information about our hoist design and electric hoist price in Pakistan, please contact our team, or email us to discuss how we can meet your specific material handling needs in Pakistan.

https://www.craneskit.com/32-ton-double-girder-hoist-for-sale-in-pakistan.html