If you are running a construction material manufacturing plant, you know how important it is to have the right lifting equipment to handle heavy loads. A few months ago, DQCRANES designed and supplied a 5 ton EOT crane with single beam to Oman, for lifting heavy loads in their manufacturing plant in Oman.

Background

Oman is a country located in the Middle East. It is a member of the Gulf Cooperation Council (GCC) and has a population of over 4 million people. Oman is a major producer of oil and gas, and its economy is growing rapidly. The country is also investing heavily in infrastructure, and there is a growing demand for cranes in Oman.

Project

The project involves the installation of a 5 ton single girder EOT crane in a manufacturing plant in Oman. The crane will be used to lift heavy loads and move them from one location to another within the plant. The crane will be operated by a trained operator who will be responsible for ensuring that all safety regulations are followed.

Crane Design

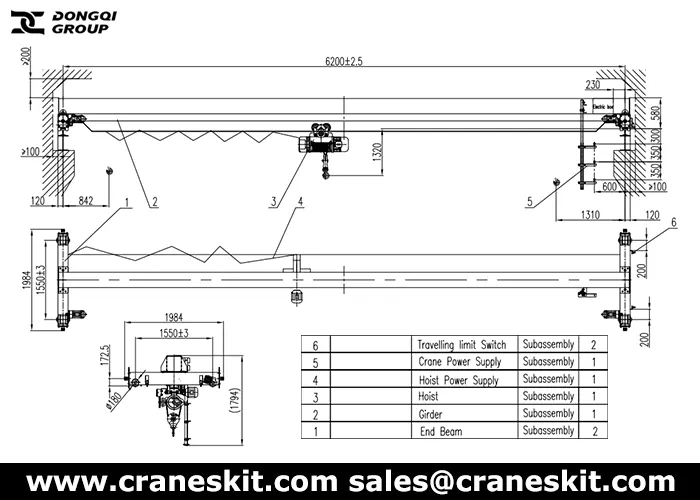

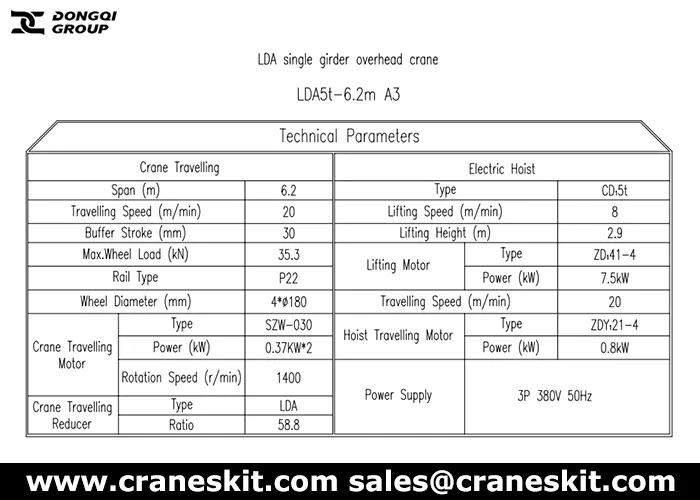

DQCRANES single girder EOT crane is designed to lift heavy loads up to 5 tons. Span 6.2m, lifting height 2.9m. The crane consists of a single girder that is supported by two end trucks. The end trucks are equipped with wheels that allow the crane to travel along a runway system. The crane is powered by an electric motor that drives a hoist mechanism. The hoist mechanism is used to lift and lower the load.

- The single girder overhead crane is designed to be operated from a control panel that is located on the ground. The operator uses the control panel to move the crane along the runway system and to lift and lower the load. The control panel is equipped with safety features that prevent the crane from operating if there is a problem.

- The crane’s single girder design ensures that it is lightweight yet robust enough to handle heavy loads. The crane’s compact design makes it easy to maneuver in tight spaces while providing maximum lifting capacity. The crane’s hoist system is powered by an electric motor, which provides smooth and precise movement.

- The 5 ton overhead crane comes equipped with advanced safety features that ensure safe operation at all times. These safety features include overload protection, emergency stop buttons, limit switches, and anti-collision devices. These features help prevent accidents and ensure the safety of workers on-site.

- The overhead crane’s control system is user-friendly and intuitive, making it easy for operators to use. The control system includes a pendant control station that allows operators to control the crane’s movement from a safe distance. This feature ensures that operators are not exposed to any potential hazards while operating the crane.

- The 5 ton single girder overhead crane has been designed with durability in mind. It is made from high-quality materials that have been tested for strength and durability. The materials used in the construction of this crane are resistant to corrosion, ensuring that it can withstand harsh environments.

The single girder EOT overhead crane for sale is an exceptional piece of machinery that has been designed to meet the needs of various industries. This single girder crane is a top-of-the-line product that has been engineered to provide superior performance and reliability. It is perfect for lifting and moving heavy loads in factories, warehouses, construction sites, and other industrial settings.

Safety Features

Safety is a top priority when it comes to operating an EOT crane. DQCRANES single girder electric traveling overhead crane has several safety features that ensure safe operation. These safety features include:

- Overload Protection: The crane is equipped with an overload protection device that prevents the crane from lifting a load that exceeds its capacity.

- Emergency Stop Button: The control panel is equipped with an emergency stop button that can be used to stop the crane in case of an emergency.

- Limit Switches: The crane is equipped with limit switches that prevent the hoist mechanism from moving beyond its safe limits.

- Anti-collision System: The crane is equipped with an anti-collision system that prevents collisions between the crane and other objects within the plant.

Production & Delivery

Installation

The installation process of the 5 ton EOT crane involves several steps. First, the runway system is installed along with the end trucks. Next, the girder is installed on top of the end trucks. Finally, the hoist mechanism and control panel are installed.

Once the installation is complete, the crane undergoes testing to ensure that it is functioning correctly. The testing involves lifting several loads of different weights to ensure that the crane can handle its maximum capacity.

Benefits

- Increased productivity: Overhead cranes can help to increase productivity in manufacturing plants by automating the lifting and moving of heavy materials. This can free up employees to focus on other tasks, such as production or quality control.

- Improved safety: Overhead cranes can help to improve safety in manufacturing plants by reducing the need for employees to lift heavy materials manually. This can help to prevent injuries and accidents.

- Reduced costs: Overhead cranes can help to reduce costs in manufacturing plants by reducing the need for manual labor and by improving efficiency.

Cranes for Sale to Manufacturing Plants

Other popular types of cranes offered by DQCRANES are also suitable for manufacturing plants:

- portable gantry crane: A portable gantry crane is a type of crane that is mounted on wheels and can be easily moved around a manufacturing plant. This type of crane is often used for tasks such as loading and unloading materials, as well as for moving heavy objects around the plant.

- jib crane: A jib crane is a type of crane that has a single arm that extends from a fixed point. This type of crane is often used for tasks such as lifting and moving materials in a confined area.

- Monorail crane: A monorail crane is a type of crane that runs on a single rail. This type of crane is often used for tasks such as lifting and moving materials in a high-traffic area, as it does not take up as much space as other types of cranes.

The type of crane that is best for a manufacturing plant will depend on the specific needs of the plant. Contact DQCRANES, our professional engineers’ teams will provide you with suitable crane solutions and affordable EOT crane price.

https://www.craneskit.com/5-ton-eot-crane-for-sale-to-oman.html