As a professional material handling solution supplier, DQCRANES has experiences in providing material handling solutions for various industries, such as, Ship building industry, Concrete product manufacturers, Heavy equipment repair facilities, Metal service centers, Galvanizing Plants , Plastic injection mold manufacturers, Power plants, Waste water treatment facilities, Automobile industry ,Aviation industry, General industry, Military applications, and many others.

DQCRANES’ overhead crane application

DQCRANES’ overhead crane application

Among the mentioned industries, DQCRANES has authority in providing solutions for the plastic injection industry for we have provided various kinds of cranes to various kinds of plastic injection workshops. Recently, we have just served a plastic company in Serbia which will be presented for your reference in the following paragraphs.

Client Company Profile

“PEŠTAN” is a private company that deals with the processing of plastic masses, PVC, polypropylene and polyethylene. The main products of “PEŠTAN” are KG (PVC) pipes, HT (PP) pipes, PE pipes, PP-R pipes, corrugated pipes, and other pipes, etc. These pipes are used for domestic and street sewerage system with appropriate coupling sleeves to remove all kinds of waste water. These pipes are manufactured in plastic injection factory, where the material are molded through injection molding. In order to provide more plastic products, the molds need to be changed. In order to provide a higher working efficiency, overhead crane and other material handling equipment are needed.

Plastic products of DQCRANES’ Serbia Client

Plastic products of DQCRANES’ Serbia Client

Material Handling Requirements

This is the case of the Serbia client, who will use the cranes in the workshop of plastic injection to lift and change molds. In order to ensure working efficiency, the Serbia client requires that the crane can work 24 hours per day. And most importantly, the safety of equipment and operators should be guaranteed. Lastly, the material handling equipment must be cost-effective and have a long service life. In order to solve their lifting problems, they came to DQCRANES for the best material handling solution for their applications.

Tour to DQCRANES’ workshop

Tour to DQCRANES’ workshop

Material Handling Solution from DQCRANES

As a responsible manufacturer, DQCRANES always thinks what the client thinks and helps him choose the optimal material handling solution. DQCRANES provides 2 solutions for Serbia clients. And as a competent crane manufacturer and supplier, DQCRANES is confident that our material handling solution is the most suitable one for the client and we are excited by the challenge for we take it as a chance to excel ourselves to provide better services and products for the clients.

Material handling solution 1

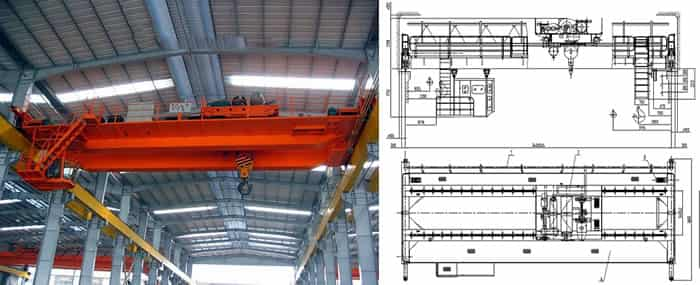

As the cranes are required to work all day(24 hours), DQCRANES advises QD model Double Girder Overhead Crane(the first drawing below), the working class of QD is A5, after technical calculations according to crane working time and working load each time. QD model overhead crane can meet the material handling demands.

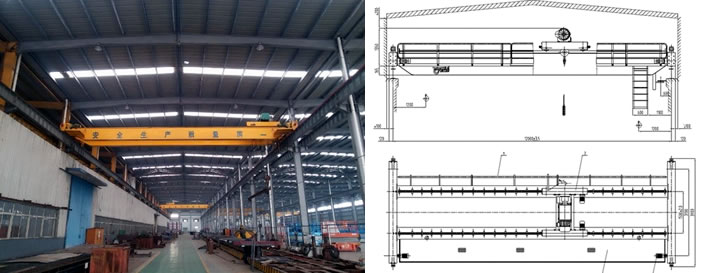

While in contact with DQCRANES, the client also gets another solution from other suppliers, it is LH model double girder overhead crane, the working class of this kind is A3. The LH crane also can meet the working demands, but the service life is shorter if the cranes keep working 24 hours per day.

Please compare the following two drawings, not only the design structure is different, but also the configurations are not the same.

QD model double girder overhead crane

QD model double girder overhead crane

LH model double girder overhead crane

LH model double girder overhead crane

Material handling solution 2

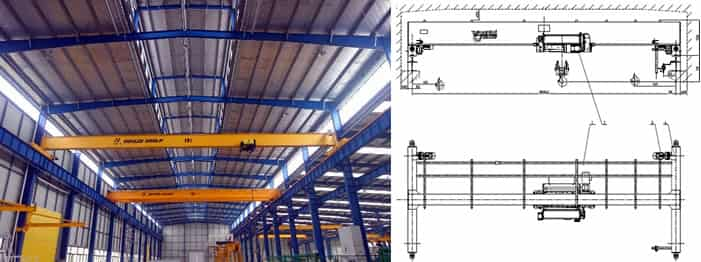

DQCRANES also provides the second solution for our clients, the European type crane.

European type cranes are the new developing trend of DQCRANES, which has the advantages of compact structure, good looking, light pressure and less maintenance. After consideration, the client prefers the traditional type crane for he thought that China has long history in manufacturing traditional type cranes, he believes DQCRANES has more advantages in traditional type.

European type overhead crane drawing and European type overhead crane example.

European type overhead crane drawing and European type overhead crane example.

Conclusion

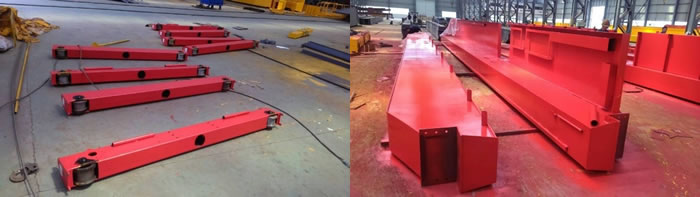

After various comparison in terms of crane quality, performance efficiency, crane price, working life, crane working class, and after-sale service, the Serbia client finally chooses DQCRANES as his partner and adopts our solution 1, that is, 2 sets QD model double girder overhead cranes and 4 sets LD model single girder overhead cranes. Up to now, the manufacturing of 2 sets QD model double girder overhead cranes and 4 sets LD model single girder overhead cranes have been finished and they are ready for delivery.

Overhead cranes for Serbia plastic injection workshop

Overhead cranes for Serbia plastic injection workshop

DQCRANES respects any option of clients and will provide more professional advice accordingly.

Now DQCRANES has enough ability to provide European type cranes, more and more clients would like to choose European type after visiting, DQCRANES will invest more in this area to improve and manufacture the best quality cranes; and just as the client said, traditional type cranes are the base of DQCRANES and we will go further on it. If you are interested in our traditional cranes and our European style cranes, or interested in the Serbia crane project and want to know more about the case, please contact us.

https://www.craneskit.com/overhead-crane-used-in-serbia-plastic-injection-industry.html